Since there seems to be interest in welding, here’s some more information.

First, some definitions that will be hard to translate to some languages:

- Soldering: Attaching two items, normally metal but could even be glass, with a third, low melting temperature metal such as lead, tin, or a mix.

- simple to do

- can attach two different metals, such as copper to steel

- low cost soldering equipment

- can use non-toxic materials for water pipes

- low strength

- Brazing: Attaching two metal items using a medium melting point metal containing copper. Typically a type of brass is used.

- harder than soldering

- typically uses a gas flame from a torch to provide enough heat

- all brass contains some lead, so technically is never completely non-toxic. For practical reasons, brass with very little lead is used for MANY plumbing fittings and connecting water pipes.

- Welding: Attaching two of the SAME material (plastic, metal, glass) using more of the SAME material. In our lessons we will be using steel.

- very strong

- requires special equipment to provide the heat needed

- more skill is required to do it

- it will not change the chemical composition of the finished item other than by very small amounts. So, if you have a stainless steel pipe and weld it using more stainless steel, it is still anti-rust and safe for food/drink.

There are different ways of performing the task of welding. For our lessons we will be using FCAW (Flux Cored Arc Weld).

You may have seen people welding with “stick” welders (SMAW = Shielded Metal Arc Weld).

In the picture below the person has bare arms. This is NEVER a good idea. Yes, I know you’re in a hurry, it’s hot, you left your jacket in the car… BUT, aside from those very hot sparks you see flying, welding gives off ultraviolet light (UV) which can give you a very bad sunburn and possibly skin cancer. At least wear a long sleeve cotton shirt (NO synthetic materials like polyester, they melt/burn easily).

The “stick” is a metal rod made of the same material you are welding, it is melted by the spark at the end which is VERY hot.

The metal rod needs to be protected from contact with air until it cools. This is accomplished by coating the metal rod with a ceramic powder mixed with glue. As the rod melts, this coating melts and flows over the top of the weld to protect it from air. When cool, you chip this off with a pointed hammer. You can see me doing this in the video with Nadezda.

Ok, but what about FCAW welding which is what we’re going to be doing?

I was getting to that. Stick welding has some drawbacks such as the stick is always getting shorter as you weld so you have to constantly adjust your position. When the stick is too short, you have to stop and put a new stick in your holder. Not a big deal if you’re welding one small item but maybe you have a lot to weld like a fence or roof for your terrace.

There’s also an issue that the stick is always electrically “hot” when the welder is on and you can accidentally make an arc and damage something. You could also get a bad electrical shock from it.

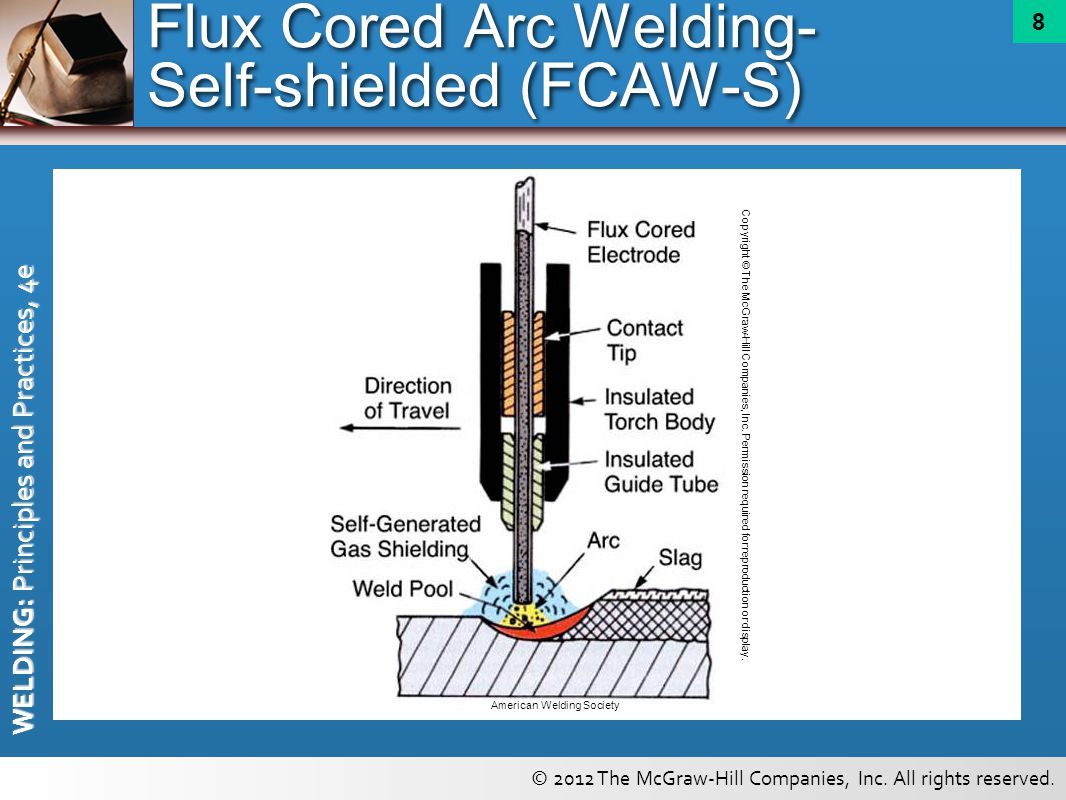

The FCAW welder takes the stick and turns it inside out and makes it safer. You have a thin metal (normally steel) tube that is filled with the ceramic powder. The tube is small enough that a long length of it can be rolled up on a spool.

Instead of holding a stick with a clamp, the wire is pulled from the spool and pushed out the handle you are holding. You can see this in the video with Nadezda, an example of this is shown below.

You’ll notice a trigger on that handle or gun, when released there is no power so this is safe to lay down anywhere. When you pull the trigger the power is turned on and a motor starts pushing wire out the tip.

Here’s a drawing of what the gun looks like inside

I will have to continue this later, it is getting close to time for students to arrive.

One response to “Welding”

It ‘s useful and interesting to read even fpr such an experienced welder as Nadezda…..

Thanks a lot!