Among other things, we will be offering lessons in the use of metal working tools so you will be able to do things like this. For safety reasons, these will have to be restricted lessons, but we’ll try to have lots of pictures and videos.

Right now we’re still setting up our shop. We haven’t built benches yet to put the tools on so all this is being done on the floor.

A task I have right now is to make axels for some ball bearing wheels for the overhead hoist we have. We temporarily mounted it to one of the roof trusses but it really should be hanging from the I-beam to it’s left.

Ok, so, on to the task at hand. I’m using flanged ball bearings that are intended for wheelbarrows as wheels. I need to make axels to mount the bearings to the metal frame that will attach to the hoist.

There’s limited choices in metal available in the local area, but I did find some 32mm diameter steel bar. I really wanted 25, but making things smaller isn’t hard.

First, I use a lathe to reduce a section of the bar to 25mm diameter. Then I reduce the end down to 20mm.

Next is to saw off the end of the rod so I just have the bit I need.

I made one of these axels with the hole before sawing, but it’s easier to saw first, hole second.

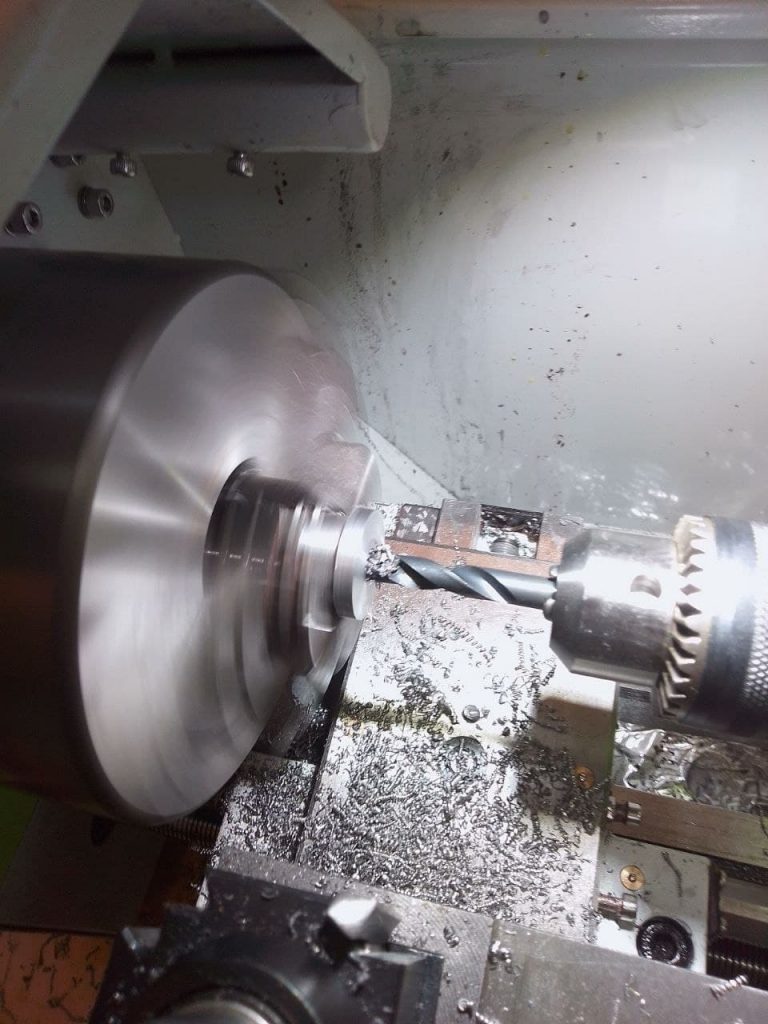

Next I put the axel back in the lathe and drill a hole all the way through it.

Now that it has a smooth hole, we need to add threads. When threading on the lathe I like doing it by hand (without using the motor). You have much better control this way. So, here is a normal tap from the hardware store cutting threads into the hole.

Test that the bolt (M10 size) fits in and there’s no defects in the threads.

And finally here’s the axel installed into the bearing. The bolt will go through the steel frame attached to the hoist. The large end on the axel keeps the bearing from sliding off. For safety the bolt will go all the way through the axel to make it extremely unlikely it would ever come out on it’s own.

That’s it for today, the next step will be to build the steel frame. Pictures and text when I start that. Probably Monday as we have a business meeting tomorrow.

Feel free to ask questions below!