A lathe is a simple, ancient machine that is still as useful as it always was. There are two basic types of lathes in use today, wood lathes that are optimized for cutting wood and “Engine” lathes which are optimized for cutting metal.

The word “Engine” does not refer to a motor. It’s ancient English that came from the French word meaning “ingenious” and refers to machines that can do something on their own.

The main thing an Engine Lathe that it does by itself is it can feed the cutting tool into the work a precise amount based on the rotation of the work. This allows making threaded parts (bolts, nuts) as well as other useful things.

Having a way to make standard bolts and nuts just by itself was a revolution. There are now specialized lathes just for making large quantities of threaded parts called a “Screw Machine”.

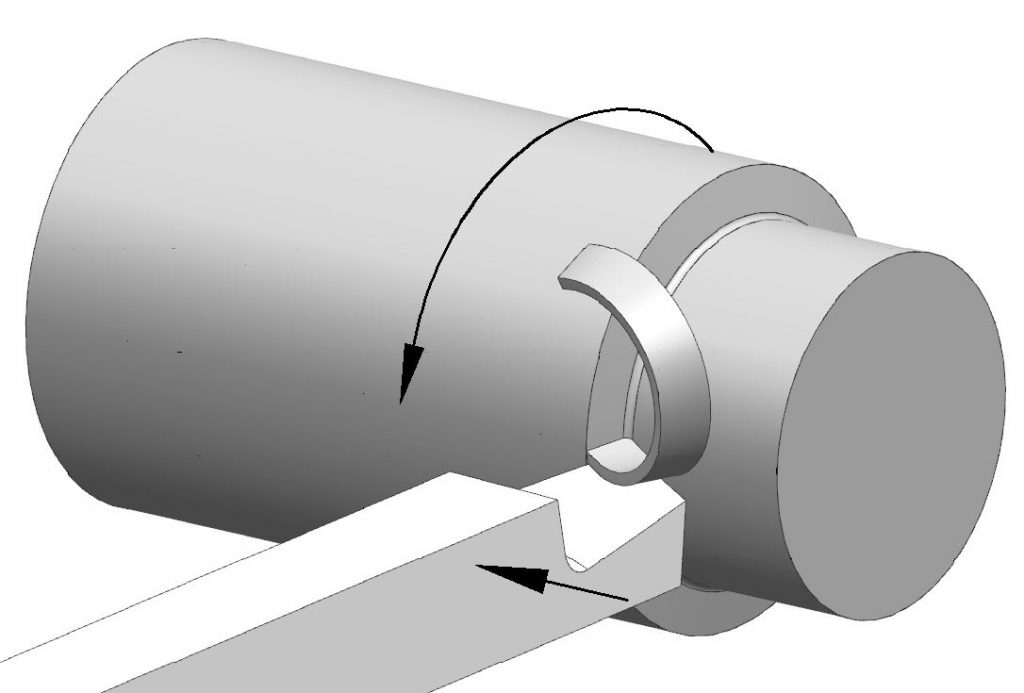

So, what is a lathe? It’s a device that rotates or turns the work while the cutting tool approaches from the side or end. Cutting on a lathe is called “turning”.

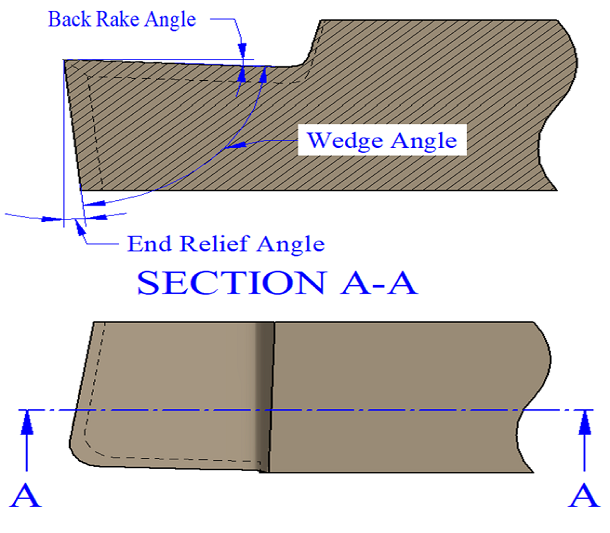

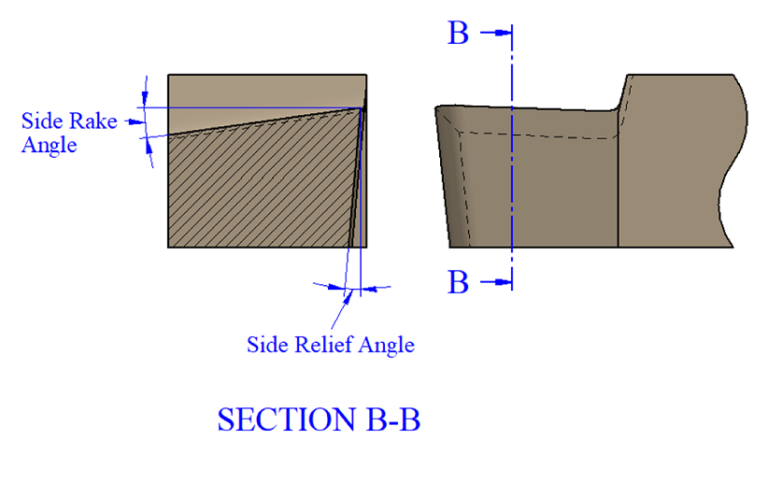

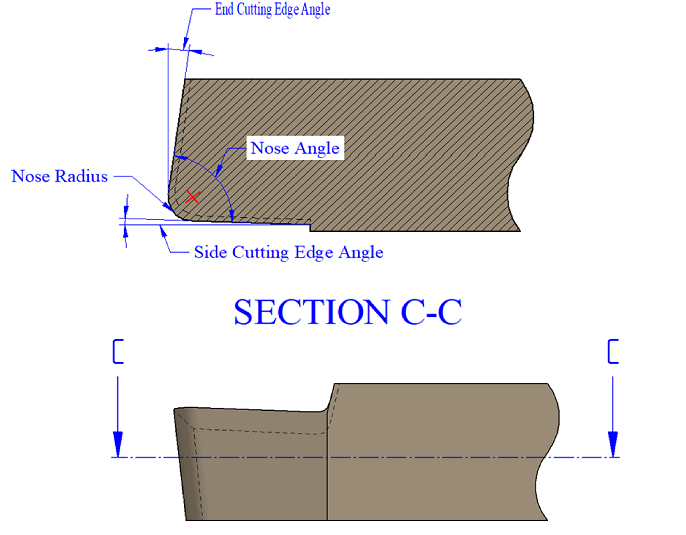

Here is how a basic tool cuts on a lathe.

And here’s a part I made back in the USA, it’s an adapter that has 3/4 inch threads on one end and M16 threads on the other.

Start the cut

repeat the cuts until the threads are deep enough

And done!

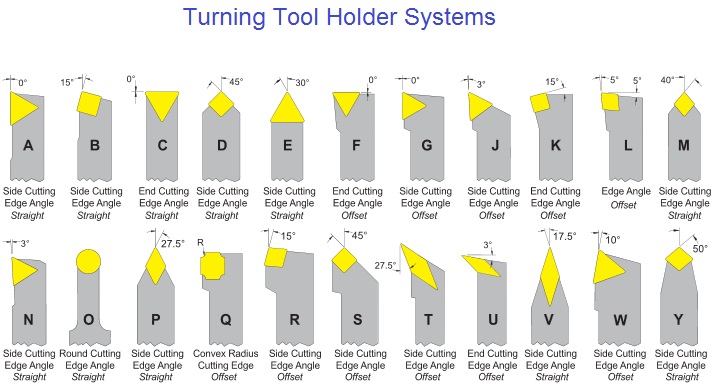

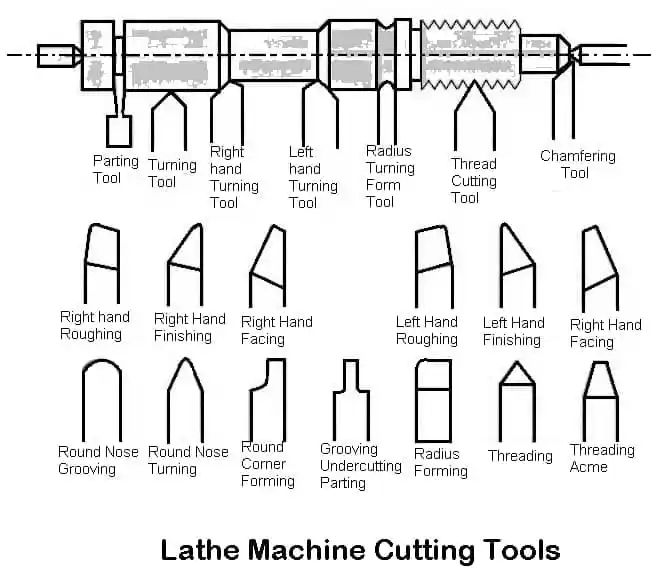

For the above I used a triangular cutter. There are many shapes of factory made cutters you can buy depending on your need.

You may also buy blank tool steel bars and grind your own shape. You make make it in a standard shape or any special shape you might need. Cutters made from ground tool steel often leave a better finish than the factory made cutters shown above.

Ground cutters and their use.

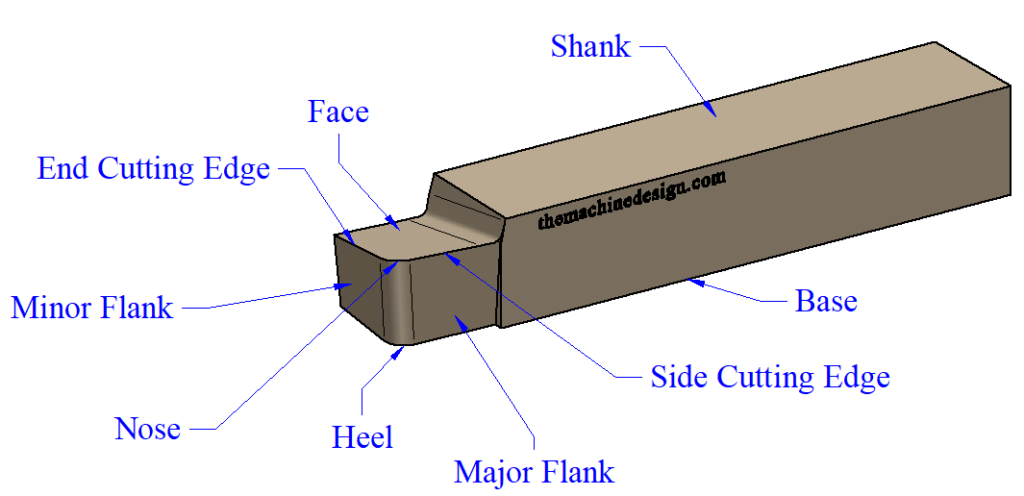

There’s more to grinding a cutting tool than just the basic shape. You need to grind the edges at an angle to make sure the tool doesn’t touch the work except at the exact edge of the cutting tip. How important this is varies with the material you are cutting and what result you need.

I know this is a lot to think about, but when you start using machine tools you’ll find there are many things that are similar between the tools. Running a machine tool is like learning to drive a car. You will be slow and very cautious at first and will make mistakes. With more practice you’ll find out how the machine acts and how to move your hands to make it do what you want. It takes patience and concentration, but learning how to use machine tools can be very useful. You might find you really like it and can get a high paying job working in a machine shop, maybe some day opening your own.

One response to “Lathe Information”

People who haven’t had a chance to see such machines not to mention that they have worked on them, may doubt that it is interesting and exciting! What a pity that schools no longer have workshops where there was an opportunity to do something on a lathe or any other machine. I am glad that my students from have the opportunity to come to the summer course at “Durand Interstellar” learning center. Sharon and Jerry will show you how the machines work and those that are already 18 years old will do their first jobs. And then the older students will share their knowledge with the younger ones! I will always be there to help you overcome the language barrier. It ‘s never too late to learn new things ! In life, it will definitely come in handy!